emissions Hog Farms photos,

Pulp mill photos, Rendering Plants,50% Honeybee Disease photos, US EPA

Coal Combuster photos

EMISSION ID/PREMEASUREMENT

&

CONTROL REDUCTION TESTS BEFORE& AFTER-photos below

Live

Animal Producers (hog/cattle/poultry) 1500-3500ppb of

ammonia/hydrogen sulfide/PM10 odor TO 13-14 ppb,

Pulp Mills - hydrogen sulfide/methyl mercaptan odor etc premeasured at

400-2500ppb TO 6ppb,

Rendering Plants -ammonia/methyl mercaptan odor measured at

600-1500ppb,

Mysterious Honeybee 50% Losses in Fall Dwindle Disease

TESTED HONEYBEES DEAD & HEALTHY OF PENN STATE WEBSITE photos

TO DETERMINE

DEATH CAUSE OF BEES "COLONY COLLAPSE DISORDER".

honeybee1.htm

We calculate control units

needed to reduce each CO, CO2, SO2, Nox, VOC, PM10/2.5 and

Mercury Air

Emissions at following levels: 4, 40, 400, 4,000, 40,000

and 400,000 TONS PER YEAR.

From 1996 to 2003, we tested our control equipment by visually

observing the air emission reductions at

power plants, forest fire

smoke

plumes, pulp mill and live animal sites.

March 25

& 26, 2004 Hog

farm test-Ohio

Ohio Pork Association Executive Director Dick Isler

(614-882-5887)

arranged an Ohio Hog producer Bill Ringler

to have us install our

control equipment

at two 5000

and 7000

hog farm sites about five miles apart for 17 hour test.

Hog SMELL

adds Hydrogen Sulfide 1500-3500 ppb. PulpSmell is Methyl

Mercaptan, Dimethyl Sulfide,

Phenols & Dimethyl Disulfide at

1-300ppb. We

eliminated these SMELLs and lowered ppb odor in 17 hours at each site.

On March 25 at 4pm, Air emission at 5000 hog farm (two10MM

gallon) lagoons measured 2711 ppb ammonia

& 3155 ppb hydrogen

sulfide.

At

7000 hog farm (two15MM gallon) lagoons, air was 3101ppb ammonia

&

3210 ppb hydrogen sulfide.

On March 26 at 8:30 am, Air emission measured at 5000 hog was down

to126 ppb

ammonia and 132 ppb

hydrogen sulfide but NO SMELL/NO ODOR and at 7000

hog farm at 9:30am measured 220 ppb ammonia

and 192 ppb hydrogen

sulfide.

Our 92-95% reduction in 17

hrs was excellent but we improved by adding secondary outside unit on

next confirmed tests.

We can do tests using Ultra Violet measurement when available to

confirm hydrogen sulfide measurements

and/or FTIR for ammonia

measurements to compare to our proprietary measurements.

A before measurements

of ammonia & hydrogen sulfide are typically

500 to 3000 ppb per

USDA & US EPA.This smell desensitizes

nasal passages & these

compounds rust

metal.

Power plants air emissions include Sulfur Dioxide(SO2)

{800-2500ppm},

Nitrogen Oxide (NOX){100-500ppm},

Carbon Monoxide

(CO){2.25ppm}, Particulate

Matter-10 micron (PM10){1.5-2.0ppm}, Particulate

Matter 2.5

micron (PM2.5) {1-2.0ppm}, Volatile Organic Compound

(VOC){NA},

Ammonia{NA} and

Hydrogen Sulfide{NA}.

We did test observations at western US power plants in

2001-03, western state forest fires, North Carolina

pulp mill in 2003

and test labs. We saw cleaner air in one to three days, NO ROTTEN EGG

SMELL

(hydrogen sulfide) & better environment.

To confirm our visual tests, we developed a proprietary measurement

capability & worked with US EPA

who implemented use of Open Path

FTIR

(fournier transformer infrared) spectrograph photos in

two or

three dimensional illustration to verify SO2, NOX, CO, PM2.5,

PM10,

VOC

and

Ammonia and Hydrogen

Sulfide with UltraViolet combination. We do

work with associations, private companies & consumers.

We

ID/PREmeasure air emissions & determine control units needed per

site.

We did tests to observe and video tape FTIR test measurments

at hog farms, pulp mills, power plants

and tested

pilot plants for fossil fuels when equipment was available or used our

proprietary measurement

method with still photos attached here.

NC HOG

FARM-June 13/14,2004-99.4% reduction ammonia & hydrogen sulfide

On June 13-18, 2004 week, we tested air emissions at

Asheboro,

NC Hog Farm. Farm has 770 hogs in

each of 11 houses & three large

lagoons. The tests show

2221 ppb of ammonia & 2242 ppb of hydrogen

ulfide on June

13,

2004 at 3pm.

We installed one primary control inside unit in office area and one

secondary

unit outside office. At 9

am

on June 14, 2004, the measurements were 13 ppb of ammonia and 14 ppb

of hydrogen sulfide but

no detectable smell or odor to tester.

We appreciate and thank Mr Roy & JoAnn

Chriscoe owners for their

cooperation to

offer their facilities for testing.

NC PULP

MILL-June 14/15,2004-98.6% reduction hydrogen sulfide

On June 14, 2004 in Roanoke Rapids, NC at 5 pm, we tested

hydrogen

sulfide air emission of pulp mill

at two offsite locations. The

first

location was 500 yards south of pulp mill stack at local Faith

Tabernacle

Church on Washington Street Extension and measured 422 ppb

of

hydrogen

sulfide. The church deacon

Eugene Parks advised us his car had

rusted out from hydrogen sulfide in air but car motor functioned very

well.

We

installed

one primary unit in church meeting room facing pulp mill. The second

location was one mile north

of pulp mill stack at Mr Mead residence on

Ray

Street in Gaston, NC & measured 1323 ppb of hydrogen sulfide.

Mr

Mead advised us this was not the worst bad-smell day. We installed one

primary unit in his home facing pulp

mill.

An outside unit was placed behind his home for secondary

clearing. We PREmeasured control units needed.

At 9 am on June 15, 2004, the results at both church 500 yards south of

pulp mill stack

and

residence one mile

north were six (6) ppb of hydrogen sulfide and

a .75" rainfall per City Planner.

Hydrogen

sulfide was reduced

by 98.6% to 99.3%.

We appreciate Pastor Charles Arnold and Deacon Eugene Parks of Faith

Tabernacle Church in Roanoke Rapids, NC

nd Mr Mead of Gaston, NC for

their cooperation and confidence in providing their facilities to

ID/measure air emissions

nd install our equipment to reduce air emissions of

Pulp Mill in

Roanoke Rapids, NC.

We

thank pulp mill owner environmental staff at International Paper for

reviewing data

results of our reducing air

emissions below the 120 ppb hydrogen sulfide air emission as a proposed

requirement by NC regulations.

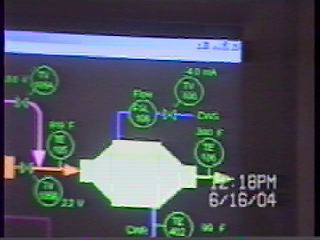

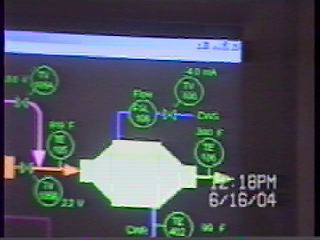

US EPA

TEST COAL COMBUSTOR EMISSIONS

On June 16, 2004 at US EPA test site in Research Triangle Park,

NC at 8

am, we observed US

EPA

contractor testing new coal combustor using natural gas to heat to

2000 F for two hours. At 10 am,

contractor switched to pulverized

bituminous coal with 18% ash and 1.5% sulfur for shake out tests.

The combustor was rated at 4 million BTU/hour using either 333 pounds

per hour of 12,000 BTU coal

or 28.8 gallons of

fuel oil or 3,840 standard cubic feet per hour of 1020 BTU natural

gas.

They operated

at 50% of capacity but still had 4000+ cubic feet per

minute of air through combustor and 1000 cubic feet

per minute flue gas

flows thru stack. The combustor system had surge

bin hopper with four hours of coal,

screw and gravity conveyor and air

flow delivery back to top of 40+ foot combustor. The flue gas

flow

was

to three heat exchangers, one bag house and one wet

scrubber with limit of 150F exit emission stack gases.

Most

plants are 270F+ without wet scrubber. EPA Contractor confirmed

.16"+ rain in 17 hrs as with lower emissions.

The US EPA had no continuous monitors attached to any portals of

combustor yet. They used a FTIR-open path

with passive mode to

measure

stack's heated exit emissions. It was to provide a clear

resolution of

infrared

measurements if temperature exit stack gases are at least 270F

but assured us they could give us

measurement

f at 150F per EPA staff person.

Our objective was to confirm our proprietary test measurements compared

with EPA's FTIR and reduce air

emissions level of flue gases. We

did measurements for Sulfur Dioxide, Carbon

Monoxide, Carbon Dioxide,

Nitrogen Oxide, Particulate Matter 10 micron,

Mercury, Hydrogen Sulfide to check US EPA. We await results

of

coal emissions by

US

EPA FTIR collected.

SUMMARY

We conclude the Hog Farms and Pulp Mill air emissions reduced an

average 5-6% an hour

during first 17 hours

with one or two primary units & secondary

unit as PREmeasured. EPA combustor plugged with ash/clinker

after 3.5 hours & operated 45-50 minutes after we activated our

primary units. It was

long enough to see same

consistent hourly reduced air emissions.

ICT

control

units

do

not emit any measurable radiation signal & are safe per David

Proffitt and

Ed

Brown of Arcadis-US EPA prime contractors & operators who stated

"your control

equipment

can

not interfere

with combustor operation". Large plants CO2 reductions are 47.1% in +

50.1% outside stack at 42 ft where backround level starts.

TEST

RESULTS

After 45 minutes, we had percentage reductions based on actual

measurements and projected reductions after17 hours as

follows:

after 45 minutes

reduction

% after 17 hrs projected

SO2 sulfur dioxide

-14%

-97.5%

CO carbon

monoxide

-26%

-97.6%

CO2 carbon dioxide

-46%

-97.6%

PM10 particulate matter 10 micron

-20%

-60% BAG house has low emissions.

Nox Nitrogen Oxide

-19.6%

-96%

Mercury

-13.7%

-90%

Hydrogen Sulfide

-10.9%

-98.3%

Each coal, oil, natural gas or other process will require one or more

primary units and secondary units based on

cubic feet per minute of

their air emission flows. The flue gas flows range may be 100 to

2,000,000 cubic feet per minute.

We are doing test using flue gases in static cell to confirm our test

measurements.

We thank US EPA at Research Triangle Park, NC for their

cooperation in helping us review, monitor and pretest

heir combustor

before and after use of our control equipment and

compare their state of art FTIR measurement

equipment to our

proprietary measurement method. A

special thanks to Mr.

Robert Hall, Mr. Shannon Senne,

Mr. Bruce Harris, Mr.Harris's

assistant, combustor

contractor employees Mr. Ed Brown and Mr. David Proffitt.

POWER

PLANTS-COAL/GAS/OIL/HYDRO

We can reduce air emissions of power plants using coal, gas or oil as

performed at US EPA coal, gas & oil plant.

See details.

HYDRO

POWER

PLANTS watersheds are 360 to 1800 square miles MUST lower

charged

air particle

density/lower fugitive air emissions to obtain normal

rainfall of .20" to.75"+ a day to improve and maintain a

onstant CFS

flow rate with head pressure to drive hydro turbines and generate

electricity. Most hydro has

100% water flow in spring

March/April/May & in fall Nov with snow melt & rainfall but

UNreasonable rainfall

June/July/Aug/Sept/Oct and Dec/Jan/Feb from

higher air pollution/ charged particle density to obtain only

38%

annual

operating rate unless water storage available.

SUGGEST HYDROs LOWER CHARGED AIR PARTICLE DENSITY/AIR

POLLUTANTS in MAY-

OCT to provide WATER for HYDRO to STORE &

OPERATE at HIGHER CAPACITY in MAY-OCT &

NOV/DEC/JAN/FEB/MAR.

You are invited to review this web page as updated

and you may contact ICT at ict4help@yahoo.com

information contained in this website is copyright and may not be used

without the express permission of ICT 2004